Wisconsin Aluminum Foundry: Collaborative Custom Design Solutions

Discover the Convenience of Aluminum Castings: Vital Facts and Services You Should Know

Light weight aluminum spreadings are significantly identified for their versatility throughout numerous markets. Their lightweight nature, corrosion resistance, and strength-to-weight proportion make them a recommended selection in numerous applications. From auto to aerospace, the convenience of these castings is remarkable. The methods of manufacturing and the variety of services offered typically go unnoticed. Recognizing these aspects can substantially affect task outcomes and performance. What necessary facts and solutions should one consider when discovering light weight aluminum castings?

The Properties That Make Light Weight Aluminum Castings Suitable for Numerous Industries

Aluminum castings have an unique mix of homes that provide them extremely ideal for a variety of markets. Their lightweight nature is just one of one of the most substantial advantages, allowing for simpler handling and lowered transport expenses (Aluminum Castings). Aluminum castings additionally exhibit exceptional deterioration resistance, which prolongs the life-span of components in difficult atmospheres. On top of that, they supply good thermal and electric conductivity, making them perfect for applications calling for reliable warmth dissipation or electric connections

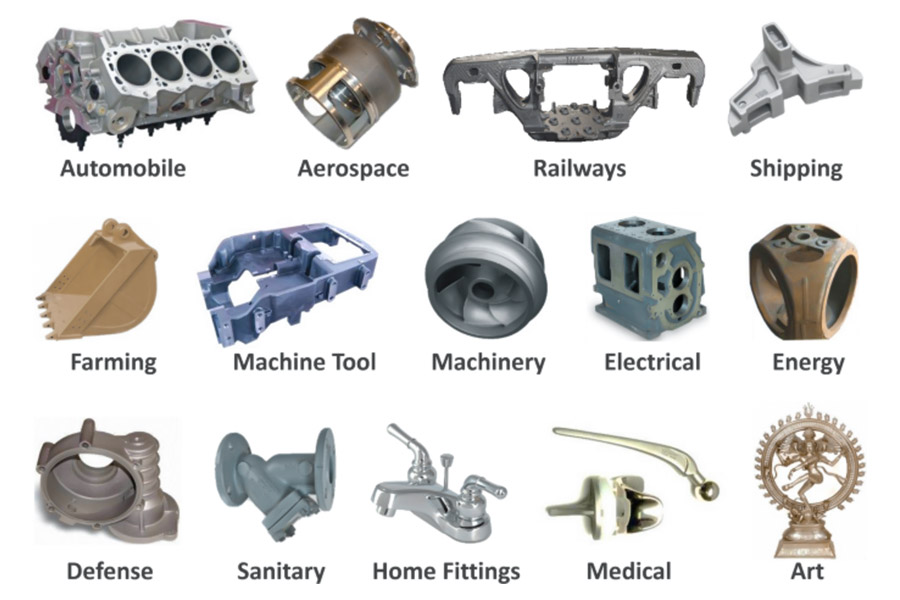

Typical Applications of Light Weight Aluminum Castings

In addition, the electrical market frequently employs light weight aluminum spreadings for real estates and enclosures, helping with reliable heat dissipation and improving safety. The customer products field utilizes light weight aluminum castings in items such as cookware and furniture, where aesthetics and functionality are extremely important.

The marine market relies on aluminum castings for parts that withstand rough atmospheres, such as boat hulls and fittings. Generally, light weight aluminum spreadings serve a wide variety of features, showcasing their flexibility and essential function in contemporary production processes.

Various Casting Methods Clarified

Recognizing the various casting techniques is vital for selecting the ideal method for light weight aluminum spreadings. Two noticeable approaches, sand spreading and die spreading, offer distinct advantages and applications. Each technique's special features influence the end product's quality and viability for particular usages.

Sand Spreading Process

While various casting methods exist, sand spreading stays one of the most widely used methods due to its adaptability and cost-effectiveness. This procedure entails producing a mold and mildew from a combination of sand and a binding representative, which creates the tooth cavity right into which liquified light weight aluminum is put. The sand mold and mildew can be conveniently formed and recycled, permitting the manufacturing of complicated geometries. Once the aluminum solidifies, the mold and mildew is damaged away, exposing the cast part. Sand casting is particularly ideal for reduced to tool production volumes, making it perfect for customized components. Its versatility to different dimensions and shapes, coupled with the capability to fit elaborate layouts, further enhances its popularity in various sectors.

Die Casting Techniques

Die spreading stands for a distinct strategy in the area of aluminum spreading techniques, supplying high precision and efficiency for automation. This method entails forcing liquified light weight aluminum into a mold and mildew under high pressure, ensuring a top quality coating and tight resistances. There Discover More Here are 2 primary types of die spreading: hot chamber and chilly chamber. Warm chamber die casting appropriates for low melting factor alloys and enables for quick production cycles. On the other hand, cool chamber pass away spreading is used for products with higher melting factors, requiring the light weight aluminum to be ladled right into the chamber. Both techniques make it possible for the production of intricate styles and complicated forms, making pass away casting a popular option for industries such as vehicle, aerospace, and customer products.

Advantages of Making Use Of Aluminum Castings

Various benefits make light weight aluminum spreadings a preferred option throughout various industries. To begin with, light weight aluminum's light-weight nature considerably lowers the general weight of items, improving their effectiveness and efficiency. Additionally, aluminum spreadings show outstanding deterioration resistance, which prolongs product lifespan and reduces maintenance costs. The material's high thermal and electrical conductivity likewise makes it perfect for applications in auto and electronic devices markets.

Light weight aluminum castings can be generated with detailed layouts, permitting producers to create complex forms that satisfy certain demands. This adaptability not only sustains ingenious designs but additionally lowers the need for added machining procedures, saving time and resources. Additionally, light weight aluminum's recyclability lines up with sustainability objectives, interesting environmentally mindful companies. Collectively, these benefits placement light weight aluminum spreadings as a remarkable option for a vast array of applications, making sure sturdiness, performance, and cost-effectiveness in today's open market.

Services Used by Light Weight Aluminum Casting Manufacturers

Additionally, they usually supply various casting techniques, such as sand casting, die spreading, and investment spreading, each click here to read suited for different project requirements. Quality control is one more essential solution, with producers executing rigorous screening and assessment methods to ensure that spreadings satisfy industry criteria.

Light weight aluminum casting companies usually assist with completing solutions, including machining, surface area therapy, and covering, enhancing the final item's sturdiness and visual allure. Finally, they might offer logistical assistance, assuring prompt distribution and effective supply chain management to fulfill client due dates.

Tips for Choosing the Right Aluminum Casting Companion

Choosing the appropriate light weight aluminum casting partner can significantly influence the success of a job (Aluminum Castings). To ensure compatibility, companies should initially assess the companion's industry experience and technical competence. A supplier with a solid history in certain applications can provide beneficial insights and innovative remedies

Next, it is vital to evaluate the quality assurance processes in position. A reliable companion will stick to strict quality standards and offer certifications where appropriate. Furthermore, assessing previous jobs and client testimonies can provide a clearer understanding of the companion's abilities and dependability.

Cost-effectiveness is likewise essential; however, it ought to not endanger top quality. Business should seek an equilibrium between expense and the degree of service supplied. Lastly, open communication and responsiveness are vital features. A companion that prioritizes cooperation fosters an efficient working connection, inevitably causing successful job results.

Often Asked Questions

Can Aluminum Castings Be Fixed if Damaged?

Yes, light weight aluminum spreadings can be repaired if damaged. Aluminum Castings. Strategies such as welding, brazing, or glue bonding are typically employed, depending upon the degree of the damages and the specific demands of the repair procedure

How Do Light Weight Aluminum Castings Compare to Various Other Metals?

Aluminum spreadings are lighter, corrosion-resistant, and more malleable contrasted to various other metals like steel or iron. Their outstanding thermal conductivity and recyclability make them a favored choice in various industries, boosting versatility and efficiency.

What Is the Life Expectancy of Aluminum Castings?

The life-span of aluminum spreadings typically varies from 10 to 50 years, depending upon environmental conditions, alloy structure, and application. Proper maintenance and protective measures can substantially enhance their toughness and longevity in various setups.

Are Light Weight Aluminum Castings Recyclable?

Yes, light weight aluminum spreadings are recyclable. They can be thawed down and repurposed without losing their intrinsic properties, making them an eco-friendly selection. This recycling process contributes to sustainability and reduces the demand for brand-new aluminum manufacturing.

How Do I Keep Light Weight Aluminum Castings?

To maintain light weight aluminum spreadings, one must frequently cleanse them to get rid of dirt and oxidation, use safety coatings to protect against deterioration, and evaluate for damage to ensure long life and structural integrity in different applications.

The flexibility of aluminum castings allows their widespread use throughout different sectors. Recognizing the numerous casting approaches is site here crucial for selecting the proper strategy for aluminum castings. Die casting represents an unique technique in the area of light weight aluminum casting techniques, supplying high accuracy and performance for mass manufacturing. Countless advantages make light weight aluminum castings a preferred choice across different markets. In addition, they generally provide numerous casting approaches, such as sand casting, die spreading, and financial investment casting, each matched for different job requirements.